Are you curious about the applications and benefits of A U-shaped Glass Tube With A Uniform Cross-sectional Area? At onlineuniforms.net, we’re not just experts in apparel; we also delve into the science of everyday tools! Let’s explore the fascinating world of U-shaped glass tubes, uncovering their uses, advantages, and the key role their uniform cross-sectional area plays. Discover how these tubes are essential in various industries, and maybe you’ll find inspiration for your next project, all while considering our fantastic uniform options for your team.

1. What is a U-Shaped Glass Tube with a Uniform Cross-Sectional Area?

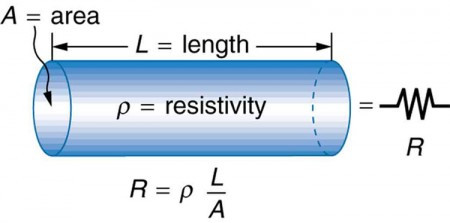

It is a tube made of glass that is bent into a U-shape, where the area of the tube’s opening is consistent throughout its length and this evenness is crucial for accuracy in scientific and industrial applications. This design ensures consistent flow and pressure distribution, making it a reliable component in many setups.

1.1. What are the Key Features of a U-Shaped Glass Tube?

Uniform cross-sectional area, U-shape, glass material and durability are important features.

- Uniform Cross-Sectional Area: Ensures consistent flow and pressure, crucial for accurate measurements and reliable performance.

- U-Shape: Allows for fluid level comparison and pressure differential measurements.

- Glass Material: Offers chemical resistance, transparency for easy observation, and thermal stability.

- Durability: Provides long-lasting use and resistance to wear in various applications.

1.2. Why is a Uniform Cross-Sectional Area Important?

A uniform cross-sectional area is vital because it ensures that the flow rate and pressure are consistent throughout the tube. This consistency is essential for accurate measurements and reliable operation in various applications.

1.3. What Types of Glass are Used for These Tubes?

Borosilicate glass, soda-lime glass, and quartz glass are used for different applications.

- Borosilicate Glass: Offers high chemical resistance and thermal stability, ideal for lab use.

- Soda-Lime Glass: More economical and suitable for general applications.

- Quartz Glass: Provides excellent thermal shock resistance and high purity for specialized uses.

2. What are the Primary Applications of U-Shaped Glass Tubes?

U-shaped glass tubes are used in manometers, barometers, diffusion studies and chemical reactions.

2.1. How are U-Shaped Tubes Used in Manometers?

Manometers utilize U-shaped tubes to measure pressure differences. The fluid levels in each arm of the tube respond to pressure variations, providing a simple and direct way to measure pressure.

2.2. How are U-Shaped Tubes Used in Barometers?

Barometers use U-shaped tubes to measure atmospheric pressure. The height of the liquid column in the tube indicates the atmospheric pressure, providing essential data for weather forecasting and climate studies.

2.3. What Role Do They Play in Diffusion Studies?

In diffusion studies, U-shaped tubes help observe how substances mix. The uniform cross-sectional area ensures consistent diffusion rates, making it easier to accurately measure and analyze the diffusion process.

2.4. How are They Used in Chemical Reactions?

U-shaped tubes are used in chemical reactions to mix reactants and observe reactions. The tube’s shape and material allow for controlled reactions and easy monitoring of the chemical processes.

3. What are the Advantages of Using Glass for U-Shaped Tubes?

The advantages are chemical resistance, transparency, thermal stability, and easy sterilization.

3.1. How Does Glass Provide Chemical Resistance?

Glass is chemically inert, meaning it doesn’t react with most substances. This makes it perfect for handling various chemicals without contamination or corrosion.

3.2. Why is Transparency Important?

Transparency allows for easy visual observation of the contents. This is essential for monitoring reactions, fluid levels, and any changes occurring inside the tube.

3.3. What is Thermal Stability and Why Does it Matter?

Thermal stability refers to glass’s ability to withstand temperature changes without breaking. This is crucial when dealing with reactions or measurements that involve heating or cooling.

3.4. How Easy is it to Sterilize Glass?

Glass can be easily sterilized using various methods like autoclaving or chemical disinfectants. This is vital in applications where cleanliness and purity are essential, such as in medical or laboratory settings.

4. How Does the Uniform Cross-Sectional Area Affect Fluid Dynamics?

The uniform cross-sectional area ensures consistent flow, reduces turbulence, and provides predictable fluid behavior.

4.1. What is Consistent Flow?

Consistent flow means that the fluid moves through the tube at a steady rate. This is important for accurate measurements and predictable system performance.

4.2. How Does it Reduce Turbulence?

A uniform cross-sectional area minimizes disruptions in the fluid flow, reducing turbulence. Less turbulence means more accurate and reliable results in experiments and processes.

4.3. What is Predictable Fluid Behavior?

Predictable fluid behavior means that the fluid’s movement follows expected patterns. This is crucial for designing and operating systems where fluid dynamics play a critical role.

5. What Industries Use U-Shaped Glass Tubes Extensively?

The industries that uses these tubes are chemical, pharmaceutical, environmental, and food and beverage.

5.1. How are They Used in the Chemical Industry?

In the chemical industry, U-shaped glass tubes are used for conducting experiments, mixing chemicals, and monitoring reactions. Their chemical resistance and transparency make them ideal for these applications.

5.2. What are Their Applications in the Pharmaceutical Industry?

In the pharmaceutical industry, these tubes are used for research, drug development, and quality control. The ability to sterilize them easily and their chemical inertness ensures the purity of pharmaceutical processes.

5.3. How are They Utilized in Environmental Monitoring?

Environmental monitoring uses U-shaped tubes for sampling and analyzing air and water quality. Their durability and resistance to environmental factors make them reliable tools for field and lab work.

5.4. What is Their Significance in the Food and Beverage Industry?

In the food and beverage industry, U-shaped tubes are used in quality control and research. They help ensure that food and beverage products meet safety and quality standards.

6. What are Some Specific Examples of U-Shaped Tube Applications?

Examples are differential pressure measurement, siphons, distillation processes, and laboratory experiments.

6.1. How are They Used for Differential Pressure Measurement?

U-shaped tubes are used in differential pressure measurement to compare the pressure between two points. This is crucial in many industrial processes to ensure optimal performance.

6.2. How Do They Function as Siphons?

As siphons, U-shaped tubes help transfer liquids from one container to another, even if the destination is higher than the source. This is useful in many practical applications.

6.3. What Role Do They Play in Distillation Processes?

In distillation processes, U-shaped tubes help in the condensation and collection of distilled substances. Their thermal stability and chemical resistance are essential for efficient distillation.

6.4. How Are They Employed in Laboratory Experiments?

U-shaped tubes are used in a wide range of laboratory experiments, from simple demonstrations to complex research projects. Their versatility and reliability make them indispensable tools in any lab.

7. How Does Temperature Affect the Performance of U-Shaped Glass Tubes?

Temperature affects fluid density, glass expansion, and the accuracy of measurements.

7.1. How Does Temperature Affect Fluid Density?

Temperature changes can alter the density of fluids within the tube, which can affect the accuracy of measurements, especially in manometers and barometers.

7.2. What is Glass Expansion?

Glass expansion refers to the change in size of the glass tube due to temperature variations. While glass has low thermal expansion, significant temperature changes can still impact the tube’s dimensions.

7.3. How Can These Effects Be Minimized?

These effects can be minimized by using glass types with low thermal expansion, such as borosilicate glass, and by calibrating instruments at different temperatures to account for fluid density changes.

8. What are the Limitations of U-Shaped Glass Tubes?

The limitations are fragility, pressure limits, readability, and size constraints.

8.1. How Fragile Are They?

Glass is a fragile material that can break easily if subjected to mechanical stress or impact. This limits their use in high-impact environments.

8.2. What are the Pressure Limits?

U-shaped glass tubes have pressure limits that restrict their use in high-pressure applications. Exceeding these limits can cause the tube to break.

8.3. How is Readability Limited?

Reading the fluid levels in a U-shaped tube can be challenging, especially with small-diameter tubes or when dealing with opaque fluids.

8.4. What are the Size Constraints?

The size of U-shaped glass tubes can be a constraint in certain applications. Very large tubes can be impractical and difficult to handle, while very small tubes may not provide accurate readings.

9. How Can You Ensure Accuracy When Using U-Shaped Glass Tubes?

Accuracy can be ensured by calibration, proper leveling, correct fluid selection, and regular maintenance.

9.1. Why is Calibration Important?

Calibration ensures that the tube provides accurate measurements by comparing its readings to a known standard. Regular calibration is essential for maintaining accuracy.

9.2. How Does Proper Leveling Help?

Proper leveling ensures that both arms of the U-shaped tube are at the same height, which is crucial for accurate pressure or fluid level measurements.

9.3. What is the Role of Correct Fluid Selection?

Selecting the correct fluid for the application is vital. The fluid should be compatible with the materials being measured and should have properties that allow for easy and accurate readings.

9.4. Why is Regular Maintenance Necessary?

Regular maintenance, including cleaning and inspection, helps ensure that the tube remains in good working condition and provides accurate measurements over time.

10. What Innovations Are Happening in U-Shaped Tube Technology?

Innovations include digital manometers, microfluidic devices, and advanced materials.

10.1. What are Digital Manometers?

Digital manometers replace traditional U-shaped tubes with electronic sensors that provide digital readings. These devices offer higher accuracy and ease of use.

10.2. What are Microfluidic Devices?

Microfluidic devices use tiny U-shaped channels to manipulate and analyze small volumes of fluids. These devices are used in a variety of applications, including medical diagnostics and chemical analysis.

10.3. How are Advanced Materials Improving U-Shaped Tubes?

Advanced materials like specialized polymers and composites are being used to create U-shaped tubes that are more durable, chemical-resistant, and able to withstand higher pressures.

11. What are the Safety Precautions When Using U-Shaped Glass Tubes?

Safety precautions include wearing protective gear, handling chemicals carefully, and proper disposal of broken glass.

11.1. What Protective Gear Should You Wear?

Wear safety goggles, gloves, and lab coats to protect yourself from chemical splashes and broken glass.

11.2. How Should Chemicals Be Handled?

Handle chemicals carefully, following all safety guidelines and using appropriate ventilation to avoid exposure to hazardous fumes.

11.3. How Should Broken Glass Be Disposed Of?

Dispose of broken glass in designated containers to prevent injuries. Use a brush and dustpan to collect small pieces, and never handle broken glass with your bare hands.

12. Can U-Shaped Tubes Be Customized for Specific Applications?

Yes, customization options include varying the tube diameter, length, material, and adding coatings.

12.1. How Can Tube Diameter Be Varied?

The diameter of the U-shaped tube can be varied to suit specific flow rate and measurement requirements. Smaller diameters are used for precise measurements, while larger diameters are used for higher flow rates.

12.2. How Does Length Customization Help?

The length of the tube can be customized to meet the specific space requirements of the application. Longer tubes can provide more accurate readings in certain scenarios.

12.3. What Materials Can Be Used?

Different materials, such as borosilicate glass, quartz, or specialized polymers, can be used to provide specific properties like chemical resistance, thermal stability, or durability.

12.4. How Do Coatings Enhance Performance?

Coatings can be added to the interior or exterior of the tube to enhance its performance. For example, hydrophobic coatings can prevent fluid adhesion, while protective coatings can increase durability.

13. How Do You Clean and Maintain U-Shaped Glass Tubes?

Cleaning and maintenance involve regular cleaning, avoiding harsh chemicals, and proper storage.

13.1. How Often Should You Clean Them?

Clean U-shaped glass tubes regularly to remove any contaminants that could affect their accuracy. The frequency of cleaning depends on the application and the type of materials being handled.

13.2. What Cleaning Agents Should Be Avoided?

Avoid using harsh chemicals or abrasive cleaners that could damage the glass. Instead, use mild detergents and soft brushes or cloths.

13.3. How Should They Be Stored?

Store U-shaped glass tubes in a safe place where they will not be subjected to mechanical stress or impact. Use protective cases or racks to prevent breakage.

14. What Are Some Common Problems Encountered With U-Shaped Tubes and How Can They Be Solved?

Common problems include blockages, leaks, and inaccurate readings.

14.1. How Do You Deal With Blockages?

Blockages can be cleared by flushing the tube with appropriate solvents or using a thin wire to dislodge the obstruction. Regular cleaning can help prevent blockages.

14.2. How Do You Fix Leaks?

Leaks can be fixed by replacing damaged connections or using sealants to create a tight seal. Regular inspection and maintenance can help identify and address potential leak points.

14.3. What Causes Inaccurate Readings and How Can They Be Corrected?

Inaccurate readings can be caused by a variety of factors, including calibration errors, fluid density changes, or improper leveling. Correct these issues by recalibrating the tube, accounting for temperature effects, and ensuring proper leveling.

15. How Does the Cost of U-Shaped Glass Tubes Compare to Other Measurement Devices?

U-shaped glass tubes are cost-effective, especially compared to digital and electronic devices.

15.1. What Factors Influence the Cost?

The cost of U-shaped glass tubes depends on factors such as the type of glass, size, and any custom features.

15.2. Are They a Cost-Effective Solution?

Yes, U-shaped glass tubes are a cost-effective solution for many applications, especially when compared to more complex and expensive measurement devices.

15.3. What is the Lifespan and Replacement Cost?

The lifespan of U-shaped glass tubes can be long if they are properly maintained. Replacement costs are relatively low compared to other types of equipment.

16. What Future Trends Can Be Expected in U-Shaped Tube Technology?

Future trends include integration with sensors, use in portable devices, and eco-friendly materials.

16.1. How Will They Be Integrated With Sensors?

Integrating U-shaped tubes with electronic sensors will allow for more precise and automated measurements. This will enhance their functionality and ease of use.

16.2. What Role Will They Play in Portable Devices?

Smaller, more durable U-shaped tubes will be used in portable devices for on-site measurements. This will make them more accessible and convenient for field applications.

16.3. How Will Eco-Friendly Materials Be Used?

Eco-friendly materials, such as recycled glass and biodegradable polymers, will be used to reduce the environmental impact of U-shaped tubes.

17. What Are the Ethical Considerations When Using U-Shaped Glass Tubes in Research?

Ethical considerations include data accuracy, responsible use of materials, and transparency in reporting.

17.1. Why is Data Accuracy Important?

Data accuracy is crucial for maintaining the integrity of research. Ensure that all measurements are accurate and reliable to avoid misleading results.

17.2. How Can Materials Be Used Responsibly?

Use materials responsibly by minimizing waste and recycling whenever possible. This helps reduce the environmental impact of research activities.

17.3. Why is Transparency in Reporting Necessary?

Transparency in reporting ensures that all research findings are presented honestly and accurately. This builds trust and credibility in the scientific community.

18. What Are Some Common Misconceptions About U-Shaped Glass Tubes?

Common misconceptions include that they are outdated, always inaccurate, or only for basic applications.

18.1. Are They Outdated?

No, U-shaped glass tubes are not outdated. While there are newer technologies available, they continue to be used in a wide range of applications due to their simplicity, reliability, and cost-effectiveness.

18.2. Are They Always Inaccurate?

No, U-shaped glass tubes are not always inaccurate. When properly calibrated and maintained, they can provide highly accurate measurements.

18.3. Are They Only for Basic Applications?

No, U-shaped glass tubes are not only for basic applications. They are used in a variety of complex research and industrial processes, from chemical analysis to environmental monitoring.

19. How Can U-Shaped Glass Tubes Be Used in Educational Demonstrations?

U-shaped glass tubes can be used to demonstrate principles of pressure, fluid dynamics, and capillary action.

19.1. How Can They Demonstrate Pressure?

U-shaped tubes can be used to demonstrate pressure by showing how fluid levels change in response to pressure differences. This provides a visual and intuitive way to understand pressure concepts.

19.2. How Can They Demonstrate Fluid Dynamics?

U-shaped tubes can be used to demonstrate fluid dynamics by showing how fluids flow through the tube under different conditions. This helps illustrate concepts such as viscosity, flow rate, and turbulence.

19.3. How Can They Demonstrate Capillary Action?

U-shaped tubes with narrow diameters can be used to demonstrate capillary action by showing how fluids rise against gravity due to surface tension. This provides a visual example of this important phenomenon.

20. What Resources Are Available for Learning More About U-Shaped Glass Tubes?

Resources include scientific journals, textbooks, online courses, and industry publications.

20.1. What Scientific Journals Cover This Topic?

Journals such as the “Journal of Chemical Physics,” “Analytical Chemistry,” and “Environmental Science & Technology” often publish articles related to U-shaped glass tubes and their applications.

20.2. What Textbooks Offer Information?

Textbooks on fluid mechanics, chemistry, and environmental science typically include information about U-shaped glass tubes and their uses.

20.3. What Online Courses Are Available?

Online platforms like Coursera, edX, and Udemy offer courses on related topics, such as fluid dynamics and measurement techniques, that may cover U-shaped glass tubes.

U-shaped glass tubes with a uniform cross-sectional area are invaluable tools in various scientific and industrial applications. Their unique properties make them essential for accurate measurements and reliable performance. Whether you’re in a lab, a factory, or an educational setting, understanding the capabilities and limitations of these tubes can greatly enhance your work.

At onlineuniforms.net, we understand the importance of precision and quality in every field. Just as these U-shaped tubes require specific characteristics for optimal performance, your team’s uniforms should also meet high standards of comfort, durability, and professionalism.

Ready to outfit your team with top-quality uniforms? Contact us today for a quote and discover how onlineuniforms.net can meet all your uniform needs.

Address: 1515 Commerce St, Dallas, TX 75201, United States

Phone: +1 (214) 651-8600

Website: onlineuniforms.net

U-shaped tube setup for measuring pressure differences

U-shaped tube setup for measuring pressure differences

FAQ About U-Shaped Glass Tubes with Uniform Cross-Sectional Area

Q1: What is the primary advantage of a uniform cross-sectional area in a U-shaped glass tube?

A1: The primary advantage is ensuring consistent flow and pressure throughout the tube, crucial for accurate measurements. This uniformity minimizes turbulence and provides predictable fluid behavior, essential for reliable results in various applications.

Q2: In which industries are U-shaped glass tubes commonly used?

A2: They are extensively used in the chemical, pharmaceutical, environmental, and food & beverage industries for conducting experiments, quality control, and monitoring processes. Their chemical resistance, transparency, and ease of sterilization make them indispensable.

Q3: How does temperature affect the performance of U-shaped glass tubes?

A3: Temperature affects fluid density and glass expansion, which can impact the accuracy of measurements. It’s important to use glass types with low thermal expansion and calibrate instruments at different temperatures to minimize these effects.

Q4: What are the limitations of using U-shaped glass tubes?

A4: The limitations include their fragility, pressure limits, readability challenges, and size constraints. Glass is easily breakable, and these tubes may not be suitable for high-pressure environments or applications requiring very precise readings.

Q5: How can accuracy be ensured when using U-shaped glass tubes?

A5: Accuracy can be ensured through regular calibration, proper leveling, selecting the correct fluid for the application, and performing consistent maintenance to keep the tubes in good working condition.

Q6: What safety precautions should be taken when using U-shaped glass tubes?

A6: Always wear protective gear like safety goggles and gloves, handle chemicals carefully with adequate ventilation, and dispose of broken glass in designated containers to prevent injuries.

Q7: Can U-shaped glass tubes be customized for specific applications?

A7: Yes, customization options include varying the tube diameter, length, and material, as well as adding coatings to enhance performance. Tailoring these features can optimize the tubes for specific measurement or experimental requirements.

Q8: How do you properly clean and maintain U-shaped glass tubes?

A8: Clean them regularly with mild detergents and avoid harsh chemicals. Store them in a safe place to prevent mechanical stress or impact. Regular inspection ensures they remain in good working condition.

Q9: What are some future trends in U-shaped tube technology?

A9: Future trends include integrating them with electronic sensors for automated measurements, using them in portable devices for on-site analysis, and employing eco-friendly materials to reduce environmental impact.

Q10: How do U-shaped glass tubes contribute to educational demonstrations?

A10: They effectively demonstrate principles of pressure, fluid dynamics, and capillary action, providing visual and intuitive ways to understand these concepts in educational settings.

By understanding the science and applications of U-shaped glass tubes, you can better appreciate their role in various industries and research fields. And just as these tubes are essential for precision, onlineuniforms.net is dedicated to providing high-quality, customized uniforms for your team’s professional needs.