Navigating the world of physics can be complex, especially when understanding concepts like uniform electric fields. Are you looking for a clear understanding of how uniform electric fields work and their applications in various fields? At onlineuniforms.net, we aim to simplify these concepts and also provide you with top-notch uniform solutions for your professional needs. Understanding uniform electric fields can help businesses and organizations ensure the safety and efficiency of their operations.

1. Understanding Uniform Electric Fields

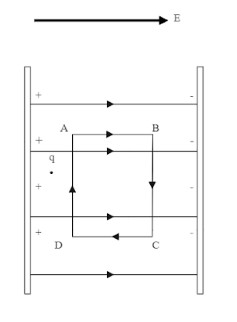

A uniform electric field is a region where the electric field strength is constant in both magnitude and direction. The electric field strength is uniform between two charged parallel plates. Let’s delve into the key aspects of uniform electric fields.

1.1. What is a Uniform Electric Field?

A uniform electric field is defined as an area where the electric field strength remains constant throughout. This means that at any point within this field, the magnitude and direction of the electric force experienced by a charge will be the same. This is the electric field strength between two charged parallel plates. This consistency makes uniform electric fields invaluable in various scientific and technological applications.

1.2. How is a Uniform Electric Field Created?

Uniform electric fields are commonly created by setting up two parallel, conductive plates with opposite charges. The electric field lines between these plates are equally spaced and run from the positive plate to the negative plate, ensuring a consistent field strength.

1.3. Characteristics of a Uniform Electric Field

The characteristics of a uniform electric field include:

- Constant Magnitude: The strength of the electric field is the same at every point.

- Consistent Direction: The direction of the field lines is parallel and uniform.

- Equal Spacing: Electric field lines are evenly spaced between the charged plates.

2. Key Components and Concepts of Electric Fields

To fully grasp the concept of a uniform electric field, it’s important to understand its fundamental components and related concepts.

2.1. Electric Potential Difference

Electric potential difference, often measured in volts, is the difference in electric potential between two points in an electric field. It represents the amount of work needed to move a unit charge from one point to another.

2.2. Electric Field Strength

Electric field strength is a vector quantity that measures the force exerted on a unit positive charge at a given point in an electric field. It is typically measured in units of volts per meter (V/m) or newtons per coulomb (N/C).

2.3. Charged Plates

Charged plates are conductive surfaces that hold an electrical charge, creating an electric field between them. When the plates are parallel and have equal but opposite charges, they produce a uniform electric field.

2.4. Electric Field Lines

Electric field lines are imaginary lines that represent the direction and strength of an electric field. In a uniform electric field, these lines are parallel and evenly spaced, indicating consistent field strength and direction.

Uniform Electric Field

Uniform Electric Field

3. Uniform Electric Field Formula

Understanding the formula for calculating the electric field strength is crucial for quantitative analysis.

3.1. Formula for Electric Field Strength

The electric field strength (E) between two parallel plates is given by:

$E = frac{V}{d}$

Where:

- ( E ) is the electric field strength (V/m or N/C)

- ( V ) is the potential difference (voltage) between the plates (V)

- ( d ) is the distance between the plates (m)

This formula indicates that the electric field strength is directly proportional to the voltage and inversely proportional to the distance between the plates.

3.2. Calculating Potential Difference

The potential difference (( V )) can be calculated if the electric field strength and distance are known:

$V = E cdot d$

This calculation is essential for designing and analyzing systems involving uniform electric fields.

3.3. Practical Examples of Calculations

For instance, if you have two plates separated by a distance of 0.05 meters with a potential difference of 100 volts, the electric field strength would be:

$E = frac{100V}{0.05m} = 2000 , V/m$

This kind of calculation is fundamental in many applications.

4. Applications of Uniform Electric Fields

Uniform electric fields are utilized across various fields due to their predictable and consistent nature.

4.1. Cathode Ray Tubes (CRTs)

CRTs, found in older television sets and oscilloscopes, use uniform electric fields to control the electron beam. The electric field guides the electrons to specific points on the screen, creating images or waveforms.

4.2. Inkjet Printers

In inkjet printers, uniform electric fields direct the charged ink droplets onto the paper. This precise control ensures high-resolution printing.

4.3. Capacitors

Capacitors store electrical energy by accumulating charge on two conductive plates separated by an insulator. The uniform electric field between these plates is crucial for the capacitor’s functionality.

4.4. Medical Equipment

Medical equipment, such as electrocardiogram (ECG) and electroencephalogram (EEG) devices, relies on uniform electric fields to measure and display the electrical activity of the heart and brain, respectively.

4.5. Scientific Research

Uniform electric fields are vital in scientific research for particle acceleration, mass spectrometry, and other experiments requiring precise control over charged particles.

5. Advantages of Using Uniform Electric Fields

Employing uniform electric fields offers several advantages that make them suitable for a wide range of applications.

5.1. Consistent Force

The consistent electric field strength ensures that charged particles experience the same force regardless of their position between the plates.

5.2. Predictable Motion

The predictable nature of the electric field allows for accurate control of charged particle motion, essential in devices like CRTs and inkjet printers.

5.3. Ease of Calculation

The uniform nature simplifies calculations, making it easier to design and analyze systems that utilize these fields.

5.4. High Precision

The precision offered by uniform electric fields is crucial in applications requiring accurate control, such as medical equipment and scientific instruments.

6. Limitations of Uniform Electric Fields

Despite their advantages, uniform electric fields also have limitations that must be considered.

6.1. Edge Effects

At the edges of the charged plates, the electric field tends to become non-uniform. These edge effects can impact the accuracy of applications relying on precise field control.

6.2. Ideal Conditions

Creating a perfectly uniform electric field requires ideal conditions, such as perfectly parallel plates and uniform charge distribution, which can be challenging to achieve in practice.

6.3. Limited Area

The uniform field is typically confined to the area between the plates. Beyond this area, the field becomes non-uniform.

6.4. Susceptibility to Interference

External electric fields or stray charges can disrupt the uniformity of the field, affecting its performance in sensitive applications.

7. Real-World Examples of Uniform Electric Fields

To better illustrate the relevance of uniform electric fields, let’s examine some real-world examples.

7.1. Electrostatic Painting

In electrostatic painting, objects are coated with paint particles that are charged and then sprayed through a uniform electric field. This ensures an even coating, reducing waste and improving finish quality.

7.2. Particle Accelerators

Particle accelerators use uniform electric fields to accelerate charged particles to high speeds for research purposes. The consistency of the field is critical for achieving desired particle energies.

7.3. Touchscreen Technology

Some touchscreen technologies use uniform electric fields to detect the position of a finger or stylus on the screen. These fields ensure accurate touch recognition.

7.4. Air Purifiers

Air purifiers use electrostatic precipitators, which employ uniform electric fields to charge and collect airborne particles, thereby cleaning the air.

8. How Uniform Electric Fields Impact Industries

The properties of uniform electric fields make them essential in various industries, influencing processes and technologies.

8.1. Manufacturing

In manufacturing, electrostatic painting and powder coating utilize uniform electric fields to apply coatings evenly, enhancing product quality and reducing material waste.

8.2. Healthcare

Healthcare benefits from uniform electric fields in diagnostic equipment like ECG and EEG machines, providing precise measurements of the body’s electrical activity.

8.3. Technology

Technology relies on uniform electric fields in devices like inkjet printers and touchscreens, ensuring high-resolution output and accurate user interfaces.

8.4. Research

Scientific research employs uniform electric fields in particle accelerators and mass spectrometers, enabling groundbreaking discoveries in physics and chemistry.

9. Advances in Uniform Electric Field Technology

Ongoing research and development continue to advance the capabilities and applications of uniform electric field technology.

9.1. Improved Materials

The development of new materials with enhanced conductivity and charge distribution properties allows for the creation of more uniform electric fields.

9.2. Precision Control Systems

Advanced control systems enable finer adjustments and maintenance of uniform electric fields, improving the accuracy of related applications.

9.3. Miniaturization

Miniaturization techniques are making it possible to create uniform electric fields in smaller devices, expanding their use in portable and micro-scale applications.

9.4. Energy Efficiency

Efforts to improve energy efficiency are leading to the development of uniform electric field systems that consume less power, making them more sustainable.

10. Innovations Driven by Uniform Electric Fields

Uniform electric fields have spurred numerous innovations across various sectors.

10.1. High-Resolution Displays

Advancements in CRT technology, driven by uniform electric fields, have led to the development of high-resolution displays with enhanced image quality.

10.2. Efficient Coating Processes

Electrostatic coating processes, utilizing uniform electric fields, have revolutionized manufacturing by providing more efficient and environmentally friendly coating solutions.

10.3. Advanced Analytical Instruments

The use of uniform electric fields in analytical instruments like mass spectrometers has enabled more precise and sensitive analysis of chemical compounds.

10.4. Medical Diagnostics

Innovations in medical diagnostics, such as improved ECG and EEG devices, have enhanced the accuracy and reliability of monitoring the body’s electrical activity.

11. Future Trends in Uniform Electric Fields

The future of uniform electric fields looks promising, with ongoing research and development paving the way for new applications and improvements.

11.1. Enhanced Precision Applications

Future applications will likely focus on enhancing the precision of existing technologies, such as medical imaging and particle beam control.

11.2. Integration with Nanotechnology

Integrating uniform electric fields with nanotechnology could lead to breakthroughs in areas like nanoelectronics and nanoscale manufacturing.

11.3. Sustainable Technologies

The development of more energy-efficient uniform electric field systems will contribute to sustainable technologies, reducing energy consumption and environmental impact.

11.4. Expanding Research Frontiers

Continued research into the fundamental properties of uniform electric fields will unlock new possibilities and expand their use in scientific exploration.

12. Safety Measures When Working with Electric Fields

Working with electric fields requires strict adherence to safety measures to prevent accidents and injuries.

12.1. Proper Grounding

Ensure that all equipment is properly grounded to prevent electric shock.

12.2. Insulation

Use insulated tools and wear appropriate protective gear, such as gloves and eye protection.

12.3. High Voltage Awareness

Be aware of the high voltages involved and maintain a safe distance from energized equipment.

12.4. Regular Inspections

Regularly inspect equipment for damage and ensure that all safety features are functioning correctly.

13. The Role of Uniforms in Maintaining Safety

In industries where uniform electric fields are used, uniforms play a crucial role in maintaining safety standards.

13.1. Material Composition

Uniforms made from non-conductive materials can protect workers from electric shock by providing an insulating layer.

13.2. Design and Fit

Properly designed uniforms that fit well can prevent accidents by ensuring that workers have full mobility and are not encumbered by loose clothing.

13.3. Visibility

High-visibility uniforms can improve safety in low-light conditions, reducing the risk of accidents involving electrical equipment.

13.4. Compliance with Standards

Uniforms that comply with industry safety standards ensure that workers are adequately protected against electrical hazards.

At onlineuniforms.net, we understand the importance of safety in the workplace. That’s why we offer a wide range of high-quality uniforms designed to meet the specific needs of various industries. Whether you need non-conductive materials, high-visibility designs, or compliance with safety standards, we have you covered.

14. Purchasing Uniforms for Electrical Safety

Choosing the right uniforms is essential for ensuring the safety of workers in environments with electric fields.

14.1. Identifying Needs

Assess the specific electrical hazards in your workplace to determine the required level of protection.

14.2. Material Selection

Choose uniforms made from non-conductive materials, such as cotton or synthetic blends, to provide insulation against electric shock.

14.3. Compliance with Standards

Ensure that the uniforms comply with relevant safety standards, such as those set by OSHA or ANSI.

14.4. Supplier Reputation

Purchase uniforms from reputable suppliers like onlineuniforms.net, known for quality and reliability.

15. Maintaining and Caring for Electrical Safety Uniforms

Proper maintenance and care are essential for preserving the protective properties of electrical safety uniforms.

15.1. Regular Cleaning

Clean uniforms regularly to remove dirt and contaminants that could compromise their insulating properties.

15.2. Inspection for Damage

Inspect uniforms regularly for tears, cuts, or other damage that could reduce their effectiveness.

15.3. Proper Storage

Store uniforms in a clean, dry place away from direct sunlight and extreme temperatures.

15.4. Following Manufacturer Instructions

Follow the manufacturer’s instructions for washing, drying, and storing uniforms to ensure they retain their protective qualities.

16. Industry Standards and Regulations for Electrical Safety Uniforms

Adhering to industry standards and regulations is crucial for ensuring the safety of workers in environments with electric fields.

16.1. OSHA Standards

The Occupational Safety and Health Administration (OSHA) sets standards for electrical safety in the workplace, including requirements for protective clothing and equipment.

16.2. ANSI Standards

The American National Standards Institute (ANSI) develops standards for electrical safety, including specifications for the design, testing, and performance of protective clothing.

16.3. NFPA Standards

The National Fire Protection Association (NFPA) publishes standards for electrical safety, including requirements for flame-resistant clothing and equipment.

16.4. Compliance Verification

Ensure that your uniforms comply with all relevant industry standards and regulations by obtaining certifications from accredited testing laboratories.

17. The Future of Uniforms in Electrical Safety

The future of uniforms in electrical safety is focused on innovation and enhanced protection.

17.1. Smart Textiles

The development of smart textiles with integrated sensors and monitoring systems will provide real-time feedback on worker safety.

17.2. Enhanced Materials

New materials with improved insulating properties and durability will offer greater protection against electrical hazards.

17.3. Customization Options

Customization options will allow for the creation of uniforms tailored to specific electrical safety needs.

17.4. Sustainability

Sustainable manufacturing practices and the use of eco-friendly materials will contribute to a more environmentally responsible approach to electrical safety.

18. Choosing onlineuniforms.net for Your Uniform Needs

When it comes to purchasing high-quality uniforms for electrical safety, onlineuniforms.net is your trusted partner.

18.1. Wide Selection

We offer a wide selection of uniforms designed to meet the specific needs of various industries.

18.2. Quality Materials

Our uniforms are made from high-quality materials that provide superior protection and durability.

18.3. Compliance with Standards

All our uniforms comply with relevant safety standards and regulations, ensuring worker safety.

18.4. Customization Options

We offer customization options to tailor uniforms to your specific requirements, including logo printing and design modifications.

18.5. Expert Support

Our team of experts is available to provide guidance and support in choosing the right uniforms for your workplace.

At onlineuniforms.net, we are committed to providing high-quality uniforms that meet the highest standards of safety and performance. Whether you’re in manufacturing, healthcare, technology, or research, our uniforms will help protect your workers and ensure a safe working environment.

19. Call to Action: Enhance Your Workplace Safety Today

Ready to enhance the safety of your workplace with high-quality uniforms from onlineuniforms.net?

19.1. Browse Our Selection

Browse our wide selection of uniforms online and find the perfect fit for your needs.

19.2. Request a Quote

Request a quote for customized uniforms tailored to your specific requirements.

19.3. Contact Us

Contact us today to speak with our team of experts and learn more about our uniform solutions.

Address: 1515 Commerce St, Dallas, TX 75201, United States

Phone: +1 (214) 651-8600

Website: onlineuniforms.net

Take the first step towards a safer workplace today with onlineuniforms.net.

20. FAQs About Uniform Electric Fields

Here are some frequently asked questions about uniform electric fields:

20.1. What is the primary use of a uniform electric field?

A uniform electric field’s primary use is to exert a consistent force on charged particles, making it essential in devices like cathode ray tubes and inkjet printers.

20.2. How does the distance between charged plates affect the electric field?

The electric field strength is inversely proportional to the distance between the plates. Increasing the distance reduces the electric field strength, while decreasing the distance increases it.

20.3. Can a uniform electric field exist in a vacuum?

Yes, a uniform electric field can exist in a vacuum as long as there are charged plates or other sources to create the field.

20.4. What happens if the charged plates are not perfectly parallel?

If the charged plates are not perfectly parallel, the electric field will not be uniform, especially near the edges.

20.5. How do external electric fields affect the uniformity?

External electric fields can disrupt the uniformity, causing variations in the electric field strength and direction.

20.6. What materials are best for creating charged plates?

Conductive materials like metals (e.g., copper, aluminum) are best for creating charged plates because they allow for uniform charge distribution.

20.7. How is a uniform electric field different from a non-uniform electric field?

In a uniform electric field, the electric field strength is constant in both magnitude and direction. In a non-uniform electric field, the strength and direction vary from point to point.

20.8. What role do insulators play in maintaining a uniform electric field?

Insulators are used to separate the charged plates and prevent charge leakage, which helps maintain the uniformity by ensuring a consistent potential difference.

20.9. How can I measure the strength of a uniform electric field?

The strength can be measured using an electrometer or by measuring the force on a known charge placed in the field.

20.10. What are the limitations of using uniform electric fields in practical applications?

Limitations include edge effects, the need for ideal conditions, and susceptibility to interference, which can affect the precision of applications.

By understanding these FAQs, you can better grasp the nuances and practical implications of uniform electric fields. And for all your uniform needs, remember to visit onlineuniforms.net for quality and reliability.