Are you looking to understand how to calculate the coefficient of uniformity for fine aggregate? At onlineuniforms.net, we provide information on aggregate material analysis, including understanding the coefficient of uniformity, and connect you with high-quality uniform solutions. Explore our site to discover uniform options tailored for durability and comfort with onlineuniforms.net.

1. What is the Coefficient of Uniformity and Why is it Important?

The coefficient of uniformity (Cu) is a calculation that reflects the particle size distribution within an aggregate sample. Understanding Cu helps determine if an aggregate is well-graded (diverse particle sizes) or poorly-graded (uniform particle sizes), which is critical for various construction applications.

- The coefficient of uniformity (Cu), also known as the uniformity coefficient, is a dimensionless parameter used to describe the range of particle sizes in a soil or aggregate sample. It’s a key indicator of how well-graded (or poorly-graded) a material is, which directly impacts its suitability for construction, filtration, and other engineering applications. A well-graded material contains a wide range of particle sizes, leading to better compaction and stability. Conversely, a poorly-graded material has a narrow range of particle sizes, which can result in lower compaction and potential instability.

- Why is it important? The coefficient of uniformity is important because it provides insights into the material’s behavior under different conditions. For example, in concrete production, a well-graded aggregate (high Cu value) contributes to a denser, stronger, and more durable final product. In filtration systems, uniformly sized particles (low Cu value) ensure consistent flow rates and prevent clogging. Therefore, understanding and calculating the Cu is essential for selecting the right aggregate for specific project requirements.

- Applications:

- Construction: Determining the suitability of aggregates for concrete, asphalt, and road base materials.

- Filtration: Designing effective filtration systems for water treatment and other industrial processes.

- Geotechnical Engineering: Assessing soil stability and permeability for foundation design and erosion control.

- onlineuniforms.net can help: While onlineuniforms.net focuses on providing a wide variety of high-quality uniforms, understanding material properties and specifications is crucial in many industries. We are dedicated to connecting you with reliable uniform options that meet the highest standards, alongside providing helpful information on related topics.

2. What is the Formula for Calculating the Coefficient of Uniformity?

The coefficient of uniformity (Cu) is calculated using the formula: Cu = D60 / D10, where D60 is the particle size at which 60% of the material passes and D10 is the particle size at which 10% of the material passes. This simple ratio offers significant insights into the grading and uniformity of aggregates.

- Breaking down the formula: The formula Cu = D60 / D10 is straightforward yet powerful. D60 represents the particle size (in mm) for which 60% of the aggregate material is finer. This means that 60% of the particles in the sample are smaller than this size. D10, on the other hand, represents the particle size for which 10% of the material is finer. This value is often referred to as the “effective size” of the aggregate.

- Understanding D60 and D10: These D-values are crucial for understanding the particle size distribution. A larger D60 indicates that the sample contains a significant amount of larger particles, while a smaller D10 suggests that the finer particles are relatively uniform in size.

- Importance of the ratio: The ratio of D60 to D10 provides a measure of the range of particle sizes present in the sample. A higher Cu value indicates a wider range of particle sizes, meaning the aggregate is well-graded. A lower Cu value indicates a narrower range of particle sizes, meaning the aggregate is poorly-graded or uniformly-graded.

- Practical example: Imagine you have an aggregate sample where D60 = 4.75 mm and D10 = 0.5 mm. Using the formula, Cu = 4.75 / 0.5 = 9.5. This high Cu value suggests that the aggregate is well-graded and contains a good distribution of particle sizes, making it suitable for applications where compaction and stability are important.

- onlineuniforms.net and Material Standards: While our primary focus at onlineuniforms.net is delivering top-notch uniform solutions, we recognize the importance of material standards across various industries. By understanding key material properties like the coefficient of uniformity, professionals can make informed decisions about the materials they use, ensuring quality and performance in their respective fields.

- Address: 1515 Commerce St, Dallas, TX 75201, United States

- Phone: +1 (214) 651-8600

- Website: onlineuniforms.net

3. What Tools Are Needed to Calculate the Coefficient of Uniformity?

Calculating the coefficient of uniformity requires a sieve analysis, which involves a set of sieves with varying mesh sizes, a mechanical sieve shaker, a weighing scale, and a calculator. The data obtained from the sieve analysis is used to determine the D60 and D10 values needed for the Cu calculation.

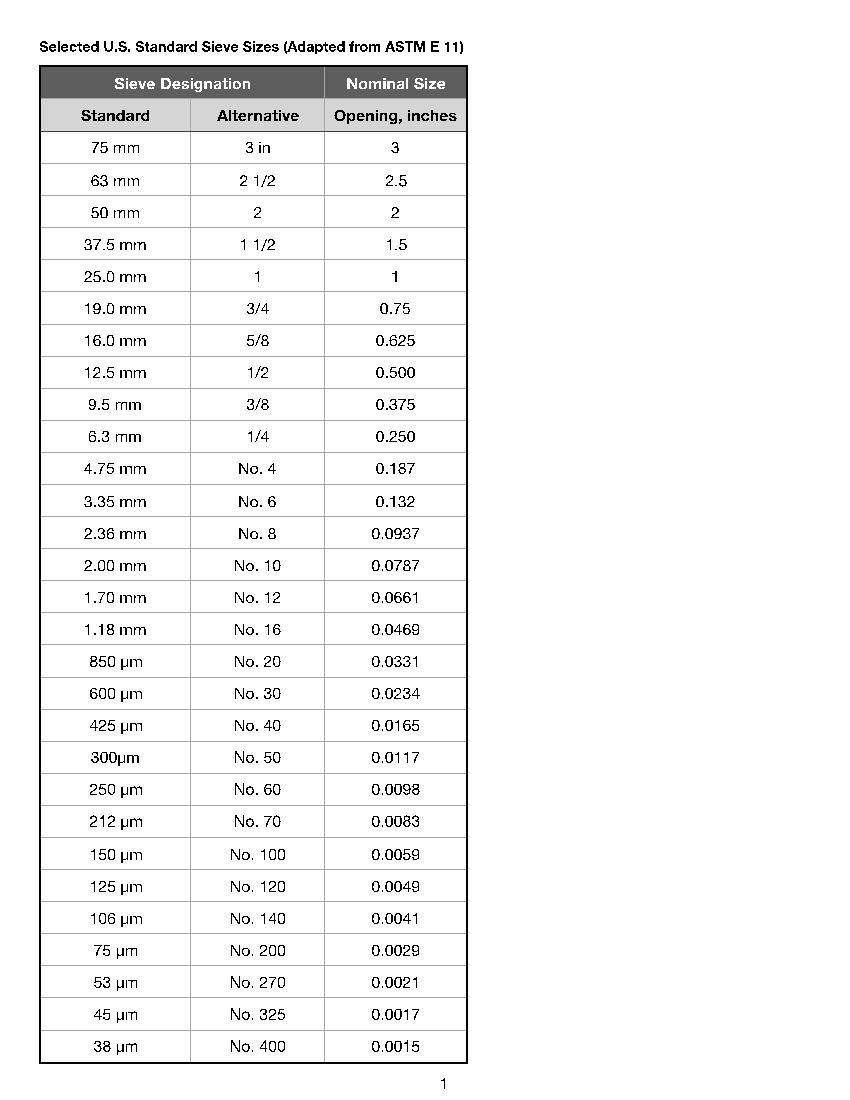

- Sieve Set: A set of sieves with varying mesh sizes is the foundation of the sieve analysis. These sieves are typically arranged in a stack, with the largest mesh size at the top and the smallest at the bottom. Standard sieve sizes are defined by organizations like ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization).

- Mechanical Sieve Shaker: A mechanical sieve shaker automates the sieving process, ensuring consistent and repeatable results. It vibrates the sieve stack for a specific duration, allowing particles to pass through the appropriate mesh sizes.

- Weighing Scale: A precise weighing scale is essential for accurately measuring the mass of the aggregate retained on each sieve. The scale should have sufficient capacity to weigh the entire sample and a readability of at least 0.1 grams.

- Calculator or Spreadsheet Software: A calculator or spreadsheet software (like Microsoft Excel or Google Sheets) is needed to perform the calculations and generate the particle size distribution curve. Spreadsheet software can also automate the calculation of the coefficient of uniformity.

- Procedure:

- Prepare the Sample: Ensure the aggregate sample is dry and representative of the material being tested.

- Weigh the Sample: Accurately weigh the total mass of the aggregate sample before sieving.

- Sieve the Sample: Arrange the sieves in the shaker and pour the sample into the top sieve.

- Shake the Sample: Operate the shaker for the recommended time (typically 10-15 minutes).

- Weigh Retained Material: Carefully weigh the material retained on each sieve.

- Calculate Percent Passing: Calculate the cumulative percent passing for each sieve size.

- Determine D60 and D10: Use the particle size distribution curve to determine the D60 and D10 values.

- Calculate Cu: Apply the formula Cu = D60 / D10 to find the coefficient of uniformity.

- onlineuniforms.net and Industry Standards: onlineuniforms.net is committed to meeting industry standards by offering dependable uniform solutions. Understanding the tools and procedures for material testing highlights the importance of quality control in various sectors.

- Address: 1515 Commerce St, Dallas, TX 75201, United States

- Phone: +1 (214) 651-8600

- Website: onlineuniforms.net

Standard Sieve Sizes

Standard Sieve Sizes

4. How to Perform a Sieve Analysis to Determine D60 and D10?

Performing a sieve analysis involves several steps to accurately determine the particle size distribution of an aggregate sample. The steps include preparing the sample, arranging the sieves, shaking the sample, weighing the retained material, and calculating the percent passing.

- Step-by-Step Guide to Sieve Analysis:

- Sample Preparation: Start by ensuring that the aggregate sample is dry and representative of the entire batch. Remove any large debris or foreign materials.

- Weighing the Sample: Accurately weigh the total mass of the aggregate sample using a calibrated weighing scale. Record this initial weight as “Total Mass.”

- Sieve Arrangement: Arrange the sieves in a stack, with the sieve having the largest opening size at the top and progressively smaller openings towards the bottom. Place a pan at the bottom of the stack to collect any material that passes through the smallest sieve.

- Shaking the Sample: Pour the weighed aggregate sample onto the top sieve. Place the entire stack into a mechanical sieve shaker and secure it properly. Set the shaker to run for a specific duration, typically 10 to 15 minutes, following ASTM or ISO standards.

- Weighing Retained Material: After shaking, carefully remove each sieve from the stack and weigh the material retained on each sieve. Record the weight of the material retained on each sieve.

- Calculating Percent Retained: Calculate the percent retained on each sieve by dividing the weight of the material retained on that sieve by the Total Mass, then multiply by 100.

- Calculating Cumulative Percent Retained: Calculate the cumulative percent retained for each sieve by adding the percent retained on that sieve to the sum of the percents retained on all sieves above it.

- Calculating Percent Passing: Calculate the percent passing for each sieve by subtracting the cumulative percent retained from 100. This indicates the percentage of the total sample that is smaller than the sieve opening size.

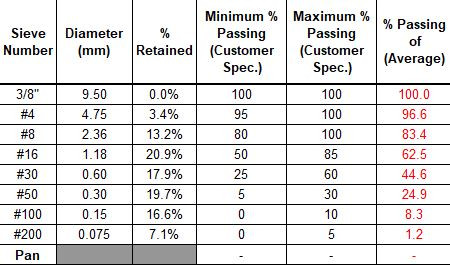

- Determining D60 and D10: Plot the percent passing values against the corresponding sieve opening sizes on a graph. This creates a particle size distribution curve. From this curve, determine the D60 and D10 values by finding the sieve opening sizes that correspond to 60% and 10% passing, respectively.

- Example Calculation:

- Suppose after plotting the data, you find that 60% of the sample passes through a sieve with an opening size of 4.75 mm (D60 = 4.75 mm).

- And 10% of the sample passes through a sieve with an opening size of 0.5 mm (D10 = 0.5 mm).

- Data Representation:

- Organize the data in a table to clearly show the sieve sizes, weight retained, percent retained, cumulative percent retained, and percent passing. This makes it easier to analyze the results and determine the D60 and D10 values accurately.

- onlineuniforms.net and Quality Assurance: onlineuniforms.net highlights the importance of precision and accuracy in all operations by providing dependable uniform solutions that meet stringent quality requirements. Understanding the step-by-step process of sieve analysis demonstrates our dedication to quality and reliability.

- Address: 1515 Commerce St, Dallas, TX 75201, United States

- Phone: +1 (214) 651-8600

- Website: onlineuniforms.net

Sieve Analysis Chart

Sieve Analysis Chart

5. What Does the Coefficient of Uniformity Value Indicate?

The coefficient of uniformity (Cu) indicates the range of particle sizes in an aggregate sample. A Cu value greater than 6 typically suggests a well-graded material, while a value less than 4 suggests a uniformly graded material.

- Interpreting Cu Values: The coefficient of uniformity (Cu) is a crucial parameter for classifying aggregate materials based on their particle size distribution. The Cu value provides insights into whether the material is well-graded, poorly-graded, or uniformly-graded.

- Cu > 6: Well-Graded Material:

- A Cu value greater than 6 indicates that the aggregate contains a wide range of particle sizes. This means that the material includes both large and small particles, resulting in a more dense and stable structure.

- Well-graded materials are ideal for applications where compaction and stability are critical, such as in concrete production, road base construction, and asphalt mixes.

- The presence of various particle sizes allows smaller particles to fill the voids between larger particles, leading to increased density and reduced permeability.

- Cu < 4: Uniformly Graded Material:

- A Cu value less than 4 suggests that the aggregate consists of particles that are mostly the same size. This indicates a narrow range of particle sizes, resulting in a less dense and less stable structure compared to well-graded materials.

- Uniformly graded materials are often used in applications where permeability is important, such as in drainage systems, filtration beds, and certain types of backfill.

- The consistent particle size allows for better water flow and reduces the risk of clogging.

- 4 ≤ Cu ≤ 6: Poorly-Graded Material:

- A Cu value between 4 and 6 indicates a material that falls between well-graded and uniformly graded. These materials may lack a sufficient range of particle sizes to achieve optimal compaction and stability.

- Poorly-graded materials may require modification or blending with other aggregates to meet specific project requirements.

- Practical Implications:

- Construction: In concrete mixes, a well-graded aggregate (high Cu) improves workability, reduces segregation, and enhances the strength and durability of the concrete.

- Filtration: In filtration systems, a uniformly graded aggregate (low Cu) ensures consistent flow rates and prevents clogging by allowing particles to pass through uniformly sized pores.

- Geotechnical Engineering: In soil stabilization, a well-graded soil (high Cu) provides better interlocking and compaction, increasing the stability of slopes and foundations.

- onlineuniforms.net and Material Performance: onlineuniforms.net is dedicated to providing uniform solutions that meet the performance requirements of various industries by understanding the implications of Cu values in material selection. This commitment to quality ensures that our uniforms meet the highest standards of durability and functionality.

- Address: 1515 Commerce St, Dallas, TX 75201, United States

- Phone: +1 (214) 651-8600

- Website: onlineuniforms.net

6. How Does the Coefficient of Uniformity Affect Aggregate Performance in Concrete?

In concrete, the coefficient of uniformity significantly impacts workability, strength, and durability. Well-graded aggregates (high Cu) improve workability and reduce segregation, while also increasing the concrete’s density and strength.

- Workability:

- Definition: Workability refers to the ease with which concrete can be mixed, placed, consolidated, and finished. It is a crucial factor in ensuring efficient construction and achieving the desired concrete properties.

- Impact of Cu: A well-graded aggregate (high Cu) improves the workability of concrete by providing a balanced distribution of particle sizes. The smaller particles fill the voids between the larger particles, reducing friction and allowing the concrete to flow more easily.

- Benefits: Improved workability leads to easier placement, reduced labor costs, and better consolidation, minimizing the risk of honeycombing and voids in the final product.

- Segregation:

- Definition: Segregation is the separation of concrete components, such as coarse aggregate, fine aggregate, and cement paste. It results in non-uniform concrete, which can compromise its strength and durability.

- Impact of Cu: Well-graded aggregates (high Cu) reduce segregation by providing a more cohesive mix. The variety of particle sizes ensures that the aggregate particles interlock effectively, preventing them from separating during mixing, transport, and placement.

- Benefits: Reduced segregation ensures a uniform distribution of aggregate, leading to consistent strength and durability throughout the concrete structure.

- Strength:

- Definition: Strength refers to the concrete’s ability to withstand compressive, tensile, and flexural forces. It is a critical factor in ensuring the structural integrity and load-bearing capacity of concrete elements.

- Impact of Cu: Well-graded aggregates (high Cu) increase the strength of concrete by providing a denser and more compact matrix. The smaller particles fill the voids between the larger particles, increasing the overall density and reducing porosity.

- Benefits: Increased density and reduced porosity result in higher compressive strength, improved resistance to cracking, and enhanced load-bearing capacity.

- Durability:

- Definition: Durability refers to the concrete’s ability to resist deterioration and maintain its properties over time when exposed to various environmental conditions, such as freeze-thaw cycles, chemical attack, and abrasion.

- Impact of Cu: Well-graded aggregates (high Cu) enhance the durability of concrete by reducing its permeability and increasing its resistance to cracking. The dense matrix created by well-graded aggregates minimizes the penetration of water and harmful substances, protecting the reinforcing steel from corrosion and reducing the risk of freeze-thaw damage.

- Benefits: Improved durability extends the service life of concrete structures, reducing maintenance costs and ensuring long-term performance.

- Practical Example:

- A concrete mix with a well-graded aggregate (Cu > 6) will exhibit excellent workability, minimal segregation, high compressive strength, and superior durability. This makes it suitable for a wide range of applications, including high-rise buildings, bridges, and pavements.

- onlineuniforms.net and Concrete Performance: onlineuniforms.net highlights the importance of selecting appropriate materials for various applications by providing uniform solutions that meet specific performance criteria. Understanding how the coefficient of uniformity affects concrete performance underscores our commitment to quality and reliability in supporting diverse industry needs.

- Address: 1515 Commerce St, Dallas, TX 75201, United States

- Phone: +1 (214) 651-8600

- Website: onlineuniforms.net

7. What is the Difference Between Well-Graded and Poorly-Graded Aggregate?

Well-graded aggregate contains a wide range of particle sizes, leading to better compaction and stability, while poorly-graded aggregate has a limited range of particle sizes, resulting in lower compaction and potential instability.

- Well-Graded Aggregate:

- Definition: Well-graded aggregate, also known as densely graded aggregate, is a material that contains a wide range of particle sizes, from large to small. This distribution allows the smaller particles to fill the voids between the larger particles, resulting in a dense and compact structure.

- Characteristics:

- Wide Range of Particle Sizes: Includes a variety of sizes, ensuring that there are particles to fill virtually all spaces between the larger particles.

- High Density: Achieves high density due to the efficient packing of particles.

- Low Permeability: Has low permeability because the voids are filled with smaller particles, reducing the flow of water.

- Good Stability: Exhibits good stability and resistance to deformation under load.

- Applications:

- Concrete Production: Ideal for concrete mixes as it improves workability, reduces segregation, and increases strength and durability.

- Road Base: Suitable for road base construction, providing a stable and load-bearing foundation.

- Asphalt Mixes: Enhances the performance and longevity of asphalt pavements.

- Poorly-Graded Aggregate:

- Definition: Poorly-graded aggregate is a material that has a limited range of particle sizes. This can either be uniformly graded (all particles are roughly the same size) or gap-graded (missing certain intermediate sizes).

- Characteristics:

- Limited Range of Particle Sizes: Consists of particles that are mostly the same size (uniformly graded) or lacks a significant portion of intermediate sizes (gap-graded).

- Lower Density: Achieves lower density compared to well-graded aggregate due to the presence of larger voids.

- High Permeability (Uniformly Graded): Uniformly graded materials have high permeability, allowing for easy water flow.

- Potential Instability: May exhibit instability and be prone to deformation under load, especially if gap-graded.

- Applications:

- Drainage Systems (Uniformly Graded): Uniformly graded materials are used in drainage systems where high permeability is required.

- Filtration Beds (Uniformly Graded): Suitable for filtration beds due to their consistent pore sizes.

- Specific Concrete Mixes (Gap-Graded): Gap-graded materials can be used in specific concrete mixes to achieve certain aesthetic or performance characteristics.

- Comparison Table:

| Feature | Well-Graded Aggregate | Poorly-Graded Aggregate |

|---|---|---|

| Particle Size Range | Wide range | Limited range |

| Density | High | Lower |

| Permeability | Low | High (uniformly graded) |

| Stability | Good | Potential instability |

| Applications | Concrete, road base, asphalt mixes | Drainage, filtration, specific mixes |

- Practical Example:

- Imagine constructing a road base. Using well-graded aggregate ensures a stable and durable foundation that can withstand heavy traffic loads. In contrast, using poorly-graded aggregate may result in a road base that is prone to settlement and deformation over time.

- onlineuniforms.net and Material Expertise: onlineuniforms.net understands the importance of material selection in various industries by providing uniform solutions tailored to meet specific needs. Knowing the differences between well-graded and poorly-graded aggregates demonstrates our commitment to offering informed solutions that support quality and performance.

- Address: 1515 Commerce St, Dallas, TX 75201, United States

- Phone: +1 (214) 651-8600

- Website: onlineuniforms.net

8. Can the Coefficient of Uniformity be Used for Soils?

Yes, the coefficient of uniformity is also used for soils to classify their particle size distribution and assess their suitability for various geotechnical applications. It helps determine the soil’s permeability, stability, and compaction characteristics.

- Application of Cu to Soils:

- Soil Classification: The coefficient of uniformity (Cu) is a valuable parameter in soil classification systems, such as the Unified Soil Classification System (USCS) and the American Association of State Highway and Transportation Officials (AASHTO) classification. It helps categorize soils based on their particle size distribution, which is crucial for predicting their engineering behavior.

- Permeability Assessment: The Cu value provides insights into the soil’s permeability, which is the ability of water to flow through it. Uniformly graded soils (low Cu) tend to have higher permeability, making them suitable for drainage applications. Well-graded soils (high Cu) generally have lower permeability due to the smaller particles filling the voids between the larger particles.

- Stability Evaluation: The Cu value is used to evaluate the stability of soil, particularly in the context of slope stability and foundation design. Well-graded soils tend to be more stable due to their dense packing and interlocking of particles, while poorly-graded soils may be more susceptible to erosion and settlement.

- Compaction Characteristics: The Cu value influences the soil’s compaction characteristics, which are important for achieving the desired density and strength in engineered fills and embankments. Well-graded soils are generally easier to compact to a high density compared to uniformly graded soils.

- Interpreting Cu Values for Soils:

- Gravels: For gravels, a Cu value greater than 4 typically indicates a well-graded material, while a value less than 4 suggests a uniformly graded material.

- Sands: For sands, a Cu value greater than 6 typically indicates a well-graded material, while a value less than 6 suggests a uniformly graded material.

- Silts and Clays: The Cu value is less commonly used for silts and clays, as these soils are primarily classified based on their plasticity and Atterberg limits rather than particle size distribution.

- Practical Applications in Geotechnical Engineering:

- Foundation Design: Understanding the Cu value of soil is essential for designing stable and durable foundations. Well-graded soils provide better support and reduce the risk of settlement.

- Slope Stabilization: Assessing the Cu value helps in implementing effective slope stabilization measures, such as soil nailing and retaining walls. Well-graded soils enhance the stability of slopes and reduce the potential for landslides.

- Erosion Control: The Cu value is considered in designing erosion control measures, such as vegetation and erosion control blankets. Well-graded soils are less prone to erosion due to their dense packing and interlocking of particles.

- Example Scenario:

- A geotechnical engineer is designing a foundation for a building on a site with sandy soil. The sieve analysis reveals that the soil has a Cu value of 7. Based on this information, the engineer can conclude that the soil is well-graded and provides a stable base for the foundation, reducing the risk of settlement.

- onlineuniforms.net and Soil Applications: onlineuniforms.net is committed to providing diverse solutions that meet the needs of various industries, including geotechnical engineering. Understanding the application of the coefficient of uniformity to soils demonstrates our dedication to supporting informed decision-making and ensuring quality in construction and infrastructure projects.

- Address: 1515 Commerce St, Dallas, TX 75201, United States

- Phone: +1 (214) 651-8600

- Website: onlineuniforms.net

9. What Are the Limitations of Using the Coefficient of Uniformity?

While useful, the coefficient of uniformity provides limited information about the overall gradation curve. It does not reveal any gaps in the grading or the presence of specific particle sizes, necessitating additional parameters like the coefficient of curvature for a complete analysis.

- Incomplete Gradation Information:

- Limited Scope: The coefficient of uniformity (Cu) only considers two points on the particle size distribution curve: D60 and D10. It does not provide information about the shape of the curve between these points or beyond them.

- Ignores Gaps: The Cu value does not reveal any gaps in the grading, where certain particle sizes are absent. A gap-graded material may have a high Cu value, suggesting a wide range of particle sizes, but it may still perform poorly due to the missing sizes.

- Oversimplification: By focusing solely on D60 and D10, the Cu value oversimplifies the complex nature of particle size distribution and may not accurately reflect the material’s overall behavior.

- Insensitivity to Particle Size Distribution:

- Similar Cu Values for Different Gradations: Different particle size distributions can result in similar Cu values. For example, two materials with different proportions of coarse and fine particles may have the same Cu value, even though their performance characteristics are significantly different.

- Misleading Interpretations: The Cu value can be misleading when used in isolation, as it does not provide a complete picture of the material’s composition. This can lead to incorrect assumptions about its suitability for specific applications.

- Need for Additional Parameters:

- Coefficient of Curvature (Cc): To overcome the limitations of the Cu value, it is often used in conjunction with the coefficient of curvature (Cc). The Cc value provides additional information about the shape of the particle size distribution curve, particularly the presence of any humps or depressions.

- Formula for Cc: The coefficient of curvature is calculated using the formula: Cc = (D30)^2 / (D10 * D60), where D30 is the particle size at which 30% of the material passes.

- Combined Interpretation: By considering both the Cu and Cc values, engineers can gain a more comprehensive understanding of the material’s particle size distribution and predict its behavior more accurately.

- Practical Implications:

- Construction Materials: In the design of concrete mixes, relying solely on the Cu value may result in a mix that is prone to segregation or bleeding. It is essential to consider the entire particle size distribution and use additional parameters like the Cc value to ensure optimal performance.

- Geotechnical Engineering: In soil stabilization projects, the Cu value alone may not accurately reflect the soil’s stability characteristics. It is necessary to conduct a thorough analysis of the soil’s gradation curve and consider other factors such as plasticity and Atterberg limits.

- onlineuniforms.net and Comprehensive Material Analysis: onlineuniforms.net is committed to supporting informed decision-making by understanding the limitations of individual parameters and promoting the use of comprehensive analysis techniques. Our dedication to quality and reliability extends to providing uniform solutions that meet specific performance requirements in various industries.

- Address: 1515 Commerce St, Dallas, TX 75201, United States

- Phone: +1 (214) 651-8600

- Website: onlineuniforms.net

10. How Can onlineuniforms.net Help with Uniform Needs?

While onlineuniforms.net focuses on providing high-quality uniform solutions, understanding aggregate properties is valuable across industries. Explore our extensive selection of uniforms tailored to meet the needs of various professions. Contact us today for personalized assistance and bulk order options.

- Extensive Uniform Selection:

- Diverse Industries: We offer a wide variety of uniforms tailored to meet the needs of various industries, including healthcare, education, hospitality, and more.

- Customizable Options: onlineuniforms.net provides customizable options, such as logo embroidery and color choices, to ensure your uniforms align with your brand identity.

- High-Quality Materials: Our uniforms are made from high-quality materials that are durable, comfortable, and easy to maintain, ensuring long-lasting performance.

- Personalized Assistance:

- Expert Guidance: Our team of uniform specialists is available to provide expert guidance and assist you in selecting the right uniforms for your specific needs.

- Size and Fit Assistance: We offer detailed size charts and fit guides to help you find the perfect fit for your employees, ensuring comfort and professionalism.

- Bulk Order Options:

- Competitive Pricing: onlineuniforms.net offers competitive pricing on bulk orders, making it affordable to outfit your entire team in high-quality uniforms.

- Efficient Order Processing: Our streamlined order processing system ensures that your bulk orders are fulfilled accurately and delivered on time, minimizing disruption to your operations.

- Commitment to Quality:

- Stringent Quality Control: We adhere to stringent quality control standards to ensure that every uniform meets our high standards for durability, comfort, and appearance.

- Customer Satisfaction Guarantee: Your satisfaction is our top priority. If you are not completely satisfied with your order, we offer a hassle-free return and exchange policy.

- Supporting Industry Standards:

- Understanding Material Properties: While our primary focus is on providing high-quality uniform solutions, we recognize the importance of understanding material properties and industry standards in various sectors.

- Reliable Solutions: onlineuniforms.net is committed to supporting informed decision-making and ensuring that our uniforms meet the specific needs of your industry.

- Call to Action:

- Explore Our Selection: Visit onlineuniforms.net to explore our extensive selection of uniforms and discover the perfect solutions for your business.

- Contact Us Today: Contact us today for personalized assistance and to discuss your bulk order options. Our team is ready to help you find the right uniforms to enhance your brand image and ensure the comfort and professionalism of your employees.

- Address: 1515 Commerce St, Dallas, TX 75201, United States

- Phone: +1 (214) 651-8600

- Website: onlineuniforms.net

Example S-Curve Diagram (gradation curve)

Example S-Curve Diagram (gradation curve)

FAQ: Coefficient of Uniformity

- What is the coefficient of uniformity (Cu)?

The coefficient of uniformity (Cu) is a measure of the particle size distribution in an aggregate or soil sample, calculated as Cu = D60 / D10. - How is the coefficient of uniformity calculated?

The coefficient of uniformity is calculated by dividing the D60 value (particle size at which 60% of the material passes) by the D10 value (particle size at which 10% of the material passes). - What does a high coefficient of uniformity indicate?

A high coefficient of uniformity (typically greater than 6) indicates a well-graded material with a wide range of particle sizes, leading to better compaction and stability. - What does a low coefficient of uniformity indicate?

A low coefficient of uniformity (typically less than 4) indicates a uniformly graded material with a narrow range of particle sizes, which may result in lower compaction and potential instability. - Why is the coefficient of uniformity important in concrete production?

The coefficient of uniformity is important in concrete production because it affects workability, segregation, strength, and durability. Well-graded aggregates (high Cu) improve these properties. - Can the coefficient of uniformity be used for soils?

Yes, the coefficient of uniformity can be used for soils to classify their particle size distribution and assess their suitability for various geotechnical applications, such as foundation design and slope stabilization. - What are the limitations of using the coefficient of uniformity?

The coefficient of uniformity provides limited information about the overall gradation curve and does not reveal any gaps in the grading or the presence of specific particle sizes. It should be used with other parameters like the coefficient of curvature for a complete analysis. - What is the difference between well-graded and poorly-graded aggregate?

Well-graded aggregate contains a wide range of particle sizes, leading to better compaction and stability, while poorly-graded aggregate has a limited range of particle sizes, resulting in lower compaction and potential instability. - How does the coefficient of uniformity affect aggregate performance in filtration systems?

In filtration systems, uniformly graded aggregates (low Cu) ensure consistent flow rates and prevent clogging by allowing particles to pass through uniformly sized pores. - Where can I find high-quality uniforms for my business?

At onlineuniforms.net, we are dedicated to providing uniform solutions that meet the performance requirements of various industries by understanding the implications of Cu values in material selection. Explore our extensive selection of uniforms tailored to meet the needs of various professions and contact us today for personalized assistance and bulk order options.- Address: 1515 Commerce St, Dallas, TX 75201, United States

- Phone: +1 (214) 651-8600

- Website: onlineuniforms.net